The Impact of High-Volume Printing on Pressure Roller Lifespan

페이지 정보

본문

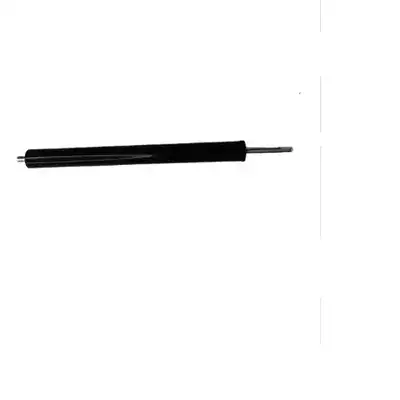

Intensive print operations place significant stress on the compression roller, a vital component in most laser and inkjet printers. This roller functions in sync with the fuser to generate thermal compression, ensuring that print pigment bonds permanently to the paper. When a printer is used relentlessly under high demand, the repetitive mechanical stress and temperature fluctuations begin to take a toll. The roller’s surface, often layered with heat-resistant compounds for consistent performance, gradually wears down. Over time, this leads to non-uniform compression, which can cause streaks, smudges, or incomplete fusing on printed pages.

In high-volume environments like enterprise environments, copy centers, and large-scale publishers, pressure rollers may be designed to process hundreds of thousands of impressions monthly. The continuous paper passage, especially when using coated stocks, cardstock, or post-consumer recycled media, speeds up deterioration. Contaminants, microfibers, and خرابی غلطک پرس پرینتر powder buildup can also build up in crevices, further degrading its performance. Even with routine maintenance, the inherent wear due to friction cannot be completely halted.

Another factor is heat. The heating unit operates at high temperatures, and the pressure roller must maintain functionality under sustained thermal load. Continuous thermal cycling can cause the roller’s compound surface to lose elasticity, become brittle, or develop fissures. Once the material loses its elasticity, it fails to maintain proper contact, resulting in blurry text, misalignment, and mechanical stoppages.

OEMs designate pressure rollers for a predetermined life expectancy before service is advised. Delaying scheduled replacements increases the risk of sudden failure. In heavy-use environments, waiting for visible signs of wear is often ineffective. Preemptive roller swaps driven by data can prevent costly downtime and maintain print consistency.

To prolong service life, users should follow manufacturer guidelines for paper types, do not exceed tray capacity, and schedule routine maintenance. Using high-quality paper reduces the generation of particulate residue and lowers friction. Additionally, giving the system downtime to regulate temperature can help mitigate heat fatigue.

Ultimately, the fuser roller is not designed for infinite use. In heavy-duty operations, its service life is proportional to how frequently it is engaged. Recognizing the signs of wear early and replacing the roller before it fails is essential for ensuring reliable, high-quality output.

- 이전글γιατί το διαδικτυακό μάρκετινγκ είναι πιο αποτελεσματικό από την παραδοσιακή διαφήμιση 25.10.08

- 다음글시알리스 작용 비아그라 당했습니다 25.10.08

댓글목록

등록된 댓글이 없습니다.