Ten Cut-Throat Shield Control Cable Tactics That Never Fails

페이지 정보

본문

The reactor course of monitoring system offers the operating personnel with data and inputs knowledge into the control and protection system. The system monitoring tightness of gasoline rod cladding specially designed for the RBMK-1500 reactors and making use of fashionable methods for detection of faulty fuel rods and laptop-based information logging supplies the core radiation control. The vertical graphite stack columns comprise gasoline channels and management rod channels. Provision is made to substitute the gas channels and control rod channels on the shut-down and cooled reactor. The unit with one reactor contains two 750 MW turbines. The separated water, in mixing with the conditioned, heated, and deaerated feedwater goes via the downcomers to the suction header and then is conveyed via suction pipes to the four principal circulating pumps considered one of which is kept within the stand-by obligation. The thermal power output of one unit is 4800 MW, the electrical power capacity is 1500 MW.

The reactor course of monitoring system offers the operating personnel with data and inputs knowledge into the control and protection system. The system monitoring tightness of gasoline rod cladding specially designed for the RBMK-1500 reactors and making use of fashionable methods for detection of faulty fuel rods and laptop-based information logging supplies the core radiation control. The vertical graphite stack columns comprise gasoline channels and management rod channels. Provision is made to substitute the gas channels and control rod channels on the shut-down and cooled reactor. The unit with one reactor contains two 750 MW turbines. The separated water, in mixing with the conditioned, heated, and deaerated feedwater goes via the downcomers to the suction header and then is conveyed via suction pipes to the four principal circulating pumps considered one of which is kept within the stand-by obligation. The thermal power output of one unit is 4800 MW, the electrical power capacity is 1500 MW.

Eeach generating unit is supplied with a gas dealing with system and unit management room. Radioactive discharge into air and water is monitored continuously using devices of the computerized radiation dose control system. The computerized radiation doze control system on the nuclear power plants with reactors of the RBMK-1500 kind is provided with amenities monitoring radiation publicity of all elements and systems of the station. To cut back radioactive aerosol emissions on the nuclear energy plants with the RBMK-1500 reactors provision is made for purification services absorbing aerosols by particular filters. The nuclear energy plants with the RBMK-1500 reactors use a closed-circuit water provide system. The Ignalina nuclear power plant, like all stations with RBMK reactors, has a direct cycle configuration - saturated steam formed within the reactor correct by passing the sunshine water by means of the reactor core is fed to the turbine at a pressure of 6,5 MPa. The turbine room, waste gasoline purification and water conditioning rooms are widespread for all of the items. The equipment and pipelines are protected against extreme stress rise by a system of steam dumping facilities which dump excess steam into the turbine condensers or into the condensation pools of the accident isolation system.

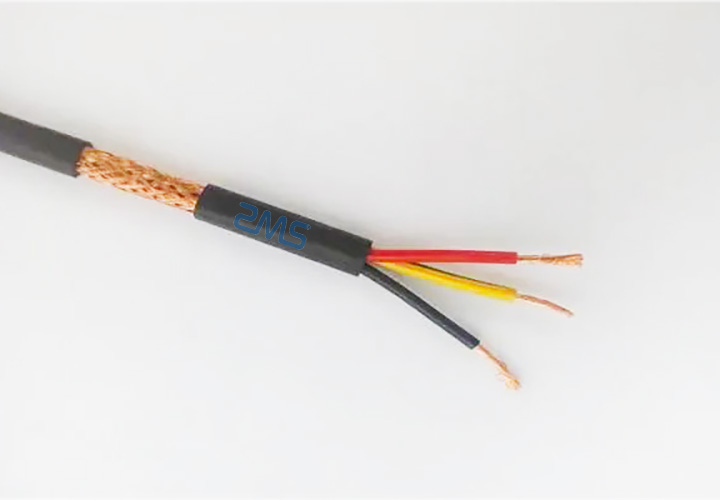

The system gives begin-up, automatic maintenance of energy on the set degree, permits management of vitality distribution along the radius and heightwise of the core, compensates for fuel burn-up, provides safety of the reactor underneath emergency circumstances. The remaining rods are unified and serve the perform of reactivity scramming, automated upkeep of the reactor energy launch at the set level, control of power distribution over the core radius. The condensate of the steam spent in the turbines is conditioned in the ion-exchangers, heated within the heat exchangers of the regenerative heating system, deaerated and on passing by way of strainers is fed again by the electric feedwater pumps over feed pipelines to the separators of the circulating circuit. The sunshine water circulates over a closed circuit. The supply pipelines convey water from the primary circulating pumps to the strain header. The pumps are of a vertical, centrifugal, single-stage configuration. Conductor Size. Conductor Configuration.

The graphite stack is carried by a welded steel construction resting on a concrete foundation. Out of the whole variety of rods, forty ones are used for energy distribution control by way of the hight of the active zone of the reactor. 24 rods perform the function of prompt emergency safequard introduced into the active zone inside 2.5 seconds below particular emergensy conditions. The bypass lines maintain pure circulation of coolant at emergency shutdown of a most important circulating pump. The circulating circuit of the reactor is a system composed of gas channels, steam/water and water lines, steam separators, main circulation pumps, strain, suction and distribution headers with related piping. The system monitoring tightness of the gas meeting claddings contains scintillation gamma-spectrometer sensors, equipment, to ensure operation and motion of sensors within the intertube area of the steam traces, and services for processing and output of information. The suction and pressure headers of every loop are interconnected by six bypass strains, every provided with a cease gate and a verify valve. The suction line of every essential circulating pump is provided with a stop gate, the supply line (down the move) mounts a examine valve, a throttle valve and a cease gate. The rated pump delivery is 8500 cu.m/h at a head of 200 m w.g., pace - one thousand rpm, electric motor output - 5500 kW.

The graphite stack is carried by a welded steel construction resting on a concrete foundation. Out of the whole variety of rods, forty ones are used for energy distribution control by way of the hight of the active zone of the reactor. 24 rods perform the function of prompt emergency safequard introduced into the active zone inside 2.5 seconds below particular emergensy conditions. The bypass lines maintain pure circulation of coolant at emergency shutdown of a most important circulating pump. The circulating circuit of the reactor is a system composed of gas channels, steam/water and water lines, steam separators, main circulation pumps, strain, suction and distribution headers with related piping. The system monitoring tightness of the gas meeting claddings contains scintillation gamma-spectrometer sensors, equipment, to ensure operation and motion of sensors within the intertube area of the steam traces, and services for processing and output of information. The suction and pressure headers of every loop are interconnected by six bypass strains, every provided with a cease gate and a verify valve. The suction line of every essential circulating pump is provided with a stop gate, the supply line (down the move) mounts a examine valve, a throttle valve and a cease gate. The rated pump delivery is 8500 cu.m/h at a head of 200 m w.g., pace - one thousand rpm, electric motor output - 5500 kW.

- 이전글The Biggest Issue With LG Fridges And Freezers, And How You Can Fix It 24.12.18

- 다음글How November 23 Bigger Jackpots In Online Bingo 24.12.18

댓글목록

등록된 댓글이 없습니다.